A steam turbine governor is a component of the turbine control system that regulates rotational speed in response to changing load conditions. The governor output signal manipulates the position of a steam inlet valve or nozzles which in turn regulates the steam flow to the turbine. In this post, we’ll explore the functions of a steam turbine in detail.

Steam Turbine Governing

A well-designed steam turbine governor provides startup and on-line control for steam turbine driven generators and mechanical drives such as compressors and pumps. The core governor application must provide configurable options that enable flexible and scalable configuration to create multiple automatic starting modes (cold, warm, and hot) as well as manual operating modes such as slow rolling and trip and throttle valve testing.

Start-Up Speed Controller and Speed/Load Controller

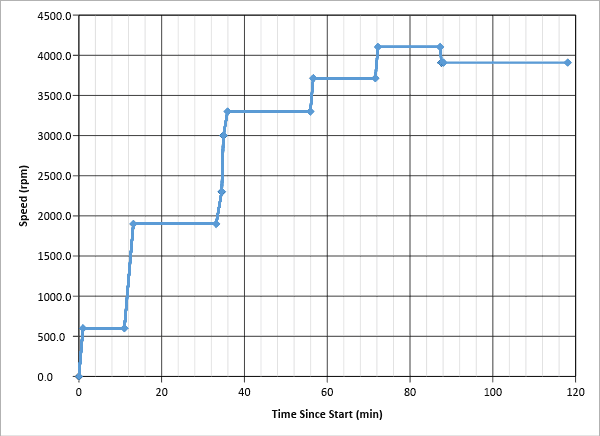

In a Petrotech provided system, the governor output signal to the steam inlet valve or nozzles is selected from two control modes, the Start-Up Speed Controller and the Speed/Load Controller. The Start-Up Speed Controller provides override control during the startup sequence for orderly ramping of the steam turbine through multiple warm up plateaus (STATES – refer to Figure 1). Once the unit reaches load speed (i.e., synchronous speed) the Start-Up Speed Controller continues to ramp until its maximum setpoint value (typically the maximum allowable speed configurable) is attained. During the starting and warmup sequence, the Start-Up Speed Controller manages the ramp rates from state to state, the speed at each state, and the dwell times of each speed plateau. Typically the ramp rates between the states are slow. This is necessary to avoid rapid and uneven expansion of the steam turbine components during the warmup period. In virtually all steam turbine systems there are operating speeds known as critical speeds which are determined during torsional and lateral analysis.

Critical speeds are operating regions where the rotational frequency nears the critical frequency and thus high vibrations occur. In these regions, the governor ramp rates are increased to provide more rapid acceleration through the critical band and thus minimize the level and duration of critical speed induced vibrations. Once the Start-Up Speed Controller brings the steam turbine to the load or rated speed, control is transitioned to the Speed/Load Controller.

Generator Drive Application

In a generator drive application, the Speed/Load Controller receives its setpoint via the governor’s speed setpoint logic and provides three different controls modes, open-breaker Proportional-Integrator (P+I) control, closed generator breaker isochronous (island mode) Proportional-Integrator-Derivative (P+I+D) control, and closed generator breaker Droop Proportional (P) only control. If available, an additional utility tie breaker signal is used to indicate isochronous or droop mode.

In isochronous mode, the Speed/Load Controller regulates the generator’s rotational speed to maintain the appropriate 50 or 60 Hz frequency. As loads (motors, lights, etc.) are added or dropped off, the Speed/Load Controller changes the position of the steam inlet valve or nozzles to maintain the speed for the appropriate frequency.

In droop mode where the generator is connected to a utility grid the generator, once synchronized, will operate at the speed that matches the grid frequency. Since utility grids are infinite relative to the generator, the only way to add power to the grid is to effectively try to increase the frequency of the grid by increasing the speed setpoint to some level above the grid frequency. In many industrial plants where users generate their own power, the Speed/Load Controller will receive its setpoint from feedforward controllers such as steam pressure or flow controllers to regulate the consumption and thus the power added to the utility grid. If for some reason the steam supply begins to decline (boiler outage or other steam demand requirements), the feedforward controller will reduce the demand signal to the droop controller and thus reduce the power generated. Conversely, when the steam supply increases, the feedforward demand signal to the droop controller will increase, and additional power will be generated.

While in droop mode, and if the utility grid tie breaker opens, the Speed/Load Controller immediately transitions to isochronous mode and assumes speed-frequency control. Once the utility tie breaker is restored droop mode resumes.

Mechanical Drive Applications

In mechanical drive applications the Speed/Load Controller, like the droop controller, receives its setpoint from feedforward controllers such as steam pressure, steam flow, or process controllers. The process controllers will vary by application depending on the service required of the mechanical drive device. The primary difference between the droop controller and mechanical drive controller is that in the mechanical drive controller, the speed range is variable.

Extraction/Admission Governors

In many process plants there is a need to have steam available at varying pressures and temperatures for different process requirements. In these applications some steam turbines also have extraction ports upstream of the final steam turbine exhaust. The steam is extracted using an additional controller which is configured to maintain the extraction steam within a manufacturer defined set of limits known as an extraction map. The extraction governor is configured to regulate the extraction within the prescribed pressure and flow limits. An admission governor works similarly to admit steam to some intermediate port on the steam turbine.

Governors/Controllers for Steam Turbines

Our team can install control systems to ensure your steam turbine is protected and efficient, including the following:

- Main Steam Valve Controls

- Speed Override Controllers

- Steam Inlet/Exit Pressure Controllers

- Load Controllers

- Steam Extraction/Admission Control

- Extraction/Admission, Minimum/Maximum Override Controllers

- Automatic Extraction/Admission Controllers

- Extraction Valve Auto-Manual Stations

Reach Out to Our Team of Experts

No matter the type used, a governor protects your turbine by reducing its load or shutting it off completely in emergency situations, as well as providing more power in the case of high demands. At Petrotech, we have the control systems available to monitor, protect, and increase the efficiency of your turbomachinery system. Our integrated control systems provide complete or partial control system retrofits for steam turbine driven packages for compression, power generation, and pumping applications. These systems provide replacement and enhancement controls for outdated electro-hydraulic, analog-electronic, relay, and pneumatic based control equipment. To learn more about our line of turbomachinery controls, explore our literature library.

First photo courtesy of Siemens published on Wikimedia Commons.