Compressor capacity control is essential for maintaining optimal system performance in industrial applications. Modern compression systems must adapt to varying load demands while maintaining efficiency and reliability. Through sophisticated control methods, operators can regulate compressor output to match system requirements precisely. This article reviews the concept of compressor capacity control, as well as the most suitable methods for controlling the capacity of reciprocating, centrifugal, and screw compressors.

What is Compressor Capacity Control

Capacity control refers to the methods that serve in adjusting a compressor’s output to match varying demands of a system. In industrial settings, load requirements often fluctuate throughout operational cycles, thus, necessitating flexible output adjustment. By implementing effective control strategies, facilities can optimize energy consumption and extend equipment life. In addition, proper capacity control helps prevent system instability and reduces wear on critical components.

The primary objective of capacity control is to maintain stable system pressure while minimizing energy consumption. As a result, modern control systems utilize various sensors and controllers to monitor operating conditions continuously. Through careful regulation of compressor output, operators can achieve significant energy savings and better system reliability. Furthermore, effective capacity control ensures consistent product quality in processes that depend on compressed air.

Reciprocating Compressor Capacity Control

Reciprocating compressors offer several methods for capacity control, each suited to specific operational requirements.

Clearance Pocket Control

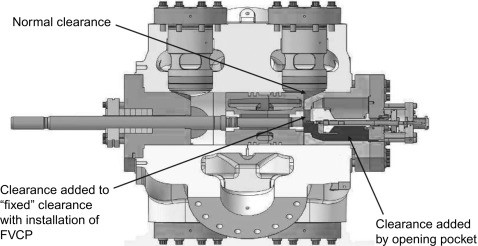

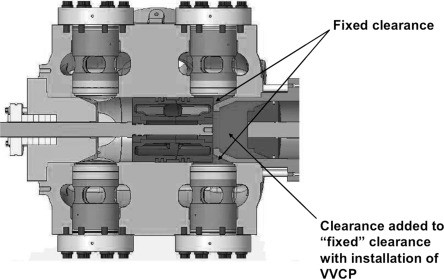

Clearance pockets are additional volumes that modify the compression ratio and capacity of reciprocating compressors. These pockets come in two distinct types: fixed volume and variable volume configurations.

- Fixed volume clearance pockets (FVCP):These are preset chambers that can be either engaged or disengaged through control valves. When activated, they provide specific capacity reduction steps, typically 25% or 50%.

- Variable volume clearance pockets (VVCP):These offer more flexible control through adjustable clearance volumes. A movable piston or plug adjusts the pocket volume continuously, hence, allowing for precise capacity modulation. This system provides stepless control within its operating range, typically 50% to 100% of full capacity. The adjustment mechanism usually employs hydraulic or pneumatic actuators for reliable operation.

Suction Valve Unloaders

By manipulating suction valve unloaders, operators can control the number of active cylinders in multi-cylinder configurations. This method provides efficient load reduction by preventing compression in selected cylinders. Unloader systems offer reliable operation with minimal maintenance requirements.

Variable Speed Control

Speed control through variable frequency drives offers another effective approach. This method provides smooth adjustment while maintaining optimal efficiency across the operating range. For applications requiring precise control, combining speed control with other methods achieves maximum flexibility.

The choice of control method depends on several key factors in industrial applications. Load profile, energy costs, and maintenance requirements influence the selection process. Modern systems often combine multiple methods to achieve optimal performance and reliability.

Centrifugal Compressor Capacity Control

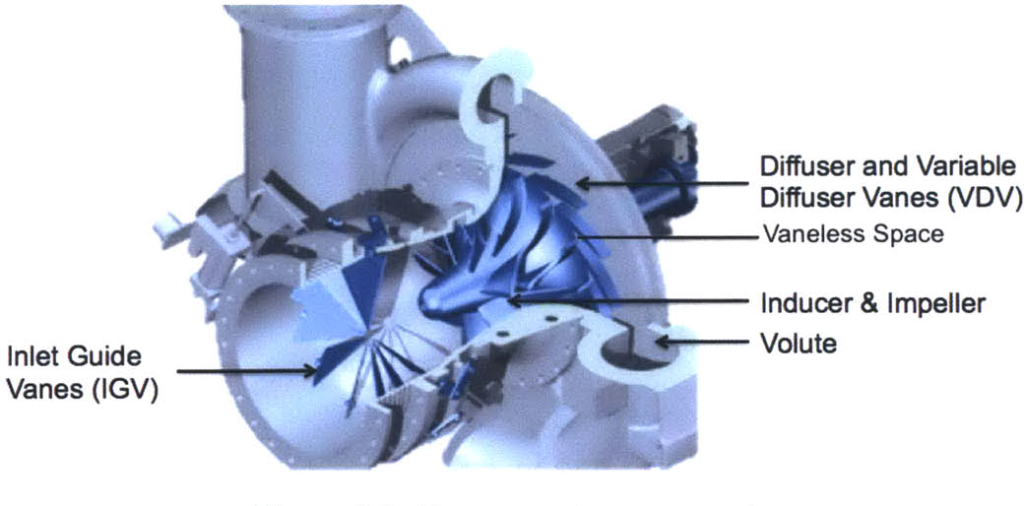

Centrifugal compressors typically employ inlet guide vanes and bypass systems for capacity control.

Inlet Guide Vane Control

Inlet guide vanes (IGVs) adjust the gas flow direction before it enters the impeller. These adjustable vanes pre-rotate the incoming gas, thereby modifying flow capacity and compression efficiency. The system typically achieves efficient capacity reduction to 40% of full load while maintaining stable operation.

Variable Diffuser Vanes

Variable diffuser vanes (VDVs) optimize flow patterns by adjusting the diffuser passage area. This combination enables capacity reduction to 50% while preventing flow separation. Moreover, proper coordination between both vane systems ensures optimal aerodynamic performance.

Anti-Surge Control

Anti-surge systems protect against damaging surge conditions by monitoring critical parameters like suction flow and discharge pressure. When surge threatens, the system opens a recycle valve to maintain minimum flow. This automatic protection ensures safe operation at low-load conditions.

Hot Gas Bypass

For very low demand periods, hot gas bypass recirculates discharge gas to the compressor inlet through cooling as well as pressure reduction. Though less efficient, this method enables operation below normal control ranges while protecting system stability.

Modern control systems coordinate these methods through microprocessor-based controllers. Advanced algorithms optimize efficiency while preventing surge conditions. This integrated approach ensures reliable operation across the entire capacity range.

Screw Compressor Capacity Control

Screw compressors utilize slide valve control and variable speed drives for capacity regulation.

Slide Valve Mechanism

The slide valve modifies the compression volume by changing the point where compression begins. This internal valve slides axially, effectively shortening the compression chamber length. The system provides stepless capacity control from 100% down to 10% load while maintaining reasonable efficiency.

Variable Speed Drive

Variable speed drives adjust motor frequency to match system demand. This method enables precise flow control and also optimal power consumption across operating ranges. Modern VFDs provide capacity control from full load down to 25%, with excellent part-load efficiency.

Spiral Valve Control

Spiral valves offer an alternative to traditional slide valves in some applications. The spiral mechanism gradually opens ports along the compression chamber. This design provides smoother capacity modulation and can reduce internal leakage in comparison to slide valves.

Turn Valve Technology

Turn valves regulate capacity by rotating to expose bypass ports in the compression chamber. This system offers quick response to demand changes and also delivers reliable operation.

Integrated Compressor Control Systems

Modern screw compressors often combine multiple control methods for optimal performance. Microprocessor controls coordinate slide valve position and speed adjustment. This integration maximizes efficiency while responding rapidly to system demand changes.

Work with Experts at Petrotech

Collaborate with our experienced compressor control specialists to optimize your system’s performance and efficiency. Our engineering team specializes in designing as well as implementing capacity control solutions for all compressor types – reciprocating, centrifugal, and screw compressors. At Petrotech, we provide comprehensive support from initial assessment through implementation and maintenance. Contact us today to discuss your compressor control requirements and also discover how our expertise can enhance your system’s reliability and efficiency.