Efficiency of Gas Turbines

Despite a shift towards greener energy resources, natural gas provides a reliable and cost-effective energy source. As a result, manufacturers continually develop new technologies that improve the efficiency of gas turbines. In this article, we explore the concept of efficiency of gas turbines, how to calculate it, and ways to improve turbine efficiency.

What is Gas Turbine Efficiency?

Generally, the measurement of turbine efficiency relates to thermal efficiency and combustion efficiency. Thermal efficiency refers to the amount of energy in the gas that gets converted into useful work such as electricity. Combustion efficiency measures how well the gas burns in the combustion chamber.

Both efficiency values are typically expressed as a percentage and can vary depending on the specific turbine design and operating conditions. Even a particular turbine’s efficiency could change at different loads or power output. To properly understand why these variations occur, it is necessary to review the basic components that make up a gas turbine.

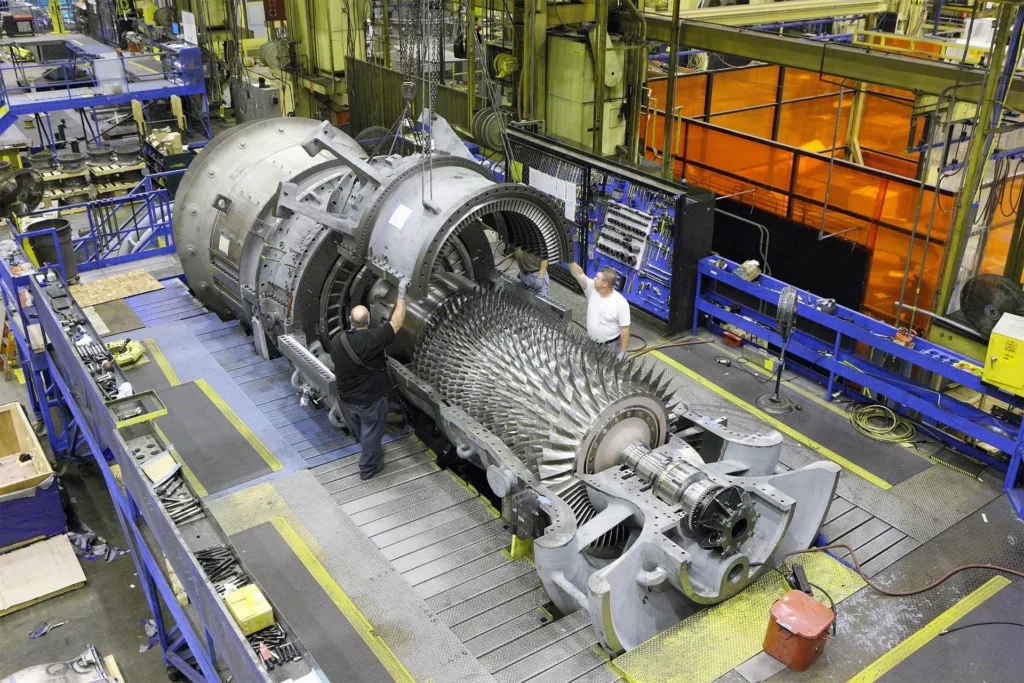

Basic Components of a Gas Turbine

Typically, all gas turbines have three main sections that enable them to function.

- Compressor: All gas turbines utilize a compressor, which intakes air, pressurizes it, and transmits it to the combustion chamber at high speeds. Most industrial setups utilize a series of compressors to satisfy pressure and flow rate requirements. The most common categories of compressors are axial and centrifugal compressors, with the former usually delivering higher efficiency values.

- Combustion Chamber: This chamber contains multiple injectors that introduce fuel to mix with the air prior to combustion. Combustion occurs at temperatures greater than 2,000℉. Hence, producing high temperature, high-pressure gas stream that enters and expands through the turbine section.

- Turbine: This section houses an intricate array of blades on a shaft that rotate due to the stream of high-temperature, high-pressure gas. The torque from these blades then transmits via its shaft to a generator to produce electricity. Also, by rotating, the turbine blades draws more pressurized air into the combustion chamber.

Factors Affecting Efficiency

Some factors that influence the efficiency of turbines include:

- Compression Ratio: This refers to the ratio of the pressure at the compressor outlet to the pressure at the compressor inlet. The higher the compression ratio, the higher the efficiency. Because, it means that air is entering the combustion chamber at higher temperature and pressure.

- Pressure Drop and Airflow: The performance of the turbine and compressor is affected by the pressure drop and airflow across their components. If there are any losses or restrictions in pressure or airflow, then there will be a reduction in efficiency.

- Turbine Inlet Temperature: As the turbine inlet temperature gets higher, it makes for more efficient energy extraction from the combustion gas.

- Ambient Conditions: In warmer atmospheric conditions, air density decreases, thus resulting in the compressor doing more work. Also, this leads to a drop in the airflow rate. Thus, there is a drop in efficiency, because air constitutes over 90% of the air-fuel combustion mixture under normal conditions.

- Mechanical Losses: Reduction in efficiency can also be due to friction between components such as bearings, seals, etc. Usually, these are accounted for and minimized during the design stage.

- Fuel Properties: The type and quality of fuel in use impacts on the gas turbine efficiency. Factors like calorific value, composition, and combustion characteristics of the fuel are important, so should be in line with specifications.

- Maintenance and Operating Conditions: Deploying a good maintenance strategy and utilizing the turbine in line with specifications help optimize efficiency.

Gas Turbine Efficiency Formula

Calculating the efficiency of a gas turbine is more tasking than a steam turbine, due to the dynamics that its vapor and vapor conditions present. Simplifying this calculation entails modelling a gas turbine’s operation after the Brayton Cycle with the following assumptions:

- The compression of air by the compressor is adiabatic.

- Combustion of the air-fuel mixture is isobaric.

- Also, the expansion of the air-fuel mixture at the turbine is adiabatic.

- The heat rejection stage that comes after the expansion of the gas stream is isobaric.

The efficiency expression for this cycle is as follows:

[Latexpage] \[ eta =1-\frac{1}{r_{p}^{\left ( \gamma -1 \right )\gamma }} \]

In this expression, the term η represents the thermal efficiency for an ideal Brayton Cycle, rp is the pressure ratio from the compressor, while γ is the adiabatic index.

Typical Efficiency Values

Various OEMs are committed to improving turbine efficiency through research & development, aerodynamics, advancement in the type of materials, as well as combustion technologies. In 2018, a Guinness World Record of 63.08% efficiency was set, but gas turbines were not always this efficient. The first simple cycle turbine developed in 1939 was operating at 18% thermal efficiency with turbine inlet temperature less than 540℃ and exhaust temperature a little over 260℃. Over the years, this value has risen to 40% with inlet temperatures of 1500℃ and exhausts up to 630℃ on larger machines. Efficiency numbers even got higher in the 1990s as Combined Cycle Gas Turbines (CCGT) gaining traction in the market. This type of turbine comes alongside better alloys, coatings, compressor ratios, more efficient heat transfer technology, etc. Today CCGT are an industry as they are more efficient, albeit at a higher cost.

How to Improve Gas Turbine Efficiency

Improving the efficiency of gas turbines remains a high industry priority as OEMs continually invest in technological developments. This section reviews some common methods that improve turbine performance.

Inlet Air Cooling

One of the major deterrents to high turbine efficiency is a low compression ratio. A significant factor that contributes to the low compression ratio is the high air inlet temperature. Moreover, the higher the air inlet temperature, the less dense the air and the more difficult to compress. However, this can be overcome by cooling the inlet air before each compression stage. Some common methods of cooling include:

- Fogging: This entails reducing the inlet air temperature by injecting atomized water into the air inlet stream after filtration. It is one of the easiest and most economical methods to deploy. However, it requires a steady water supply, can cause erosion within the compressor, and is not effective when humidity is high.

- Evaporative Cooling: Similar to fogging, this method cools the air stream after filtration by passing it through a porous media, which is constantly wetted by one or more water pumps. As there are no water droplets introduced to the air stream, this method does not cause erosion. However, it still requires a constant water supply, a large space at the inlet to install the media, and is ineffective in high humidity.

- Inlet Chilling: This is the most effective way of cooling the inlet air as it deploys cooling tubes within the air filter system. Within these tubes, chilled water is continually pumped to ensure that the inlet air does not go above a certain temperature. Thus, the working principle is similar to a refrigerator.

Heat Recovery System

When it comes to the discharge air from the compressor, having a high temperature is beneficial to the system. This is why turbine manufacturers utilize heat recovery system generators (HRSG) to boost efficiency. The HRSG is typically at the exhaust of the turbines where it captures the waste heat, and channels it to preheat air that is moving from the compressor to the combustion chamber.

Thermal Energy Storage

This entails using a system that stores the thermal energy generated by the turbine for later use. As a result, the turbine can generate energy during off-peak periods, which is then stored, and serves during on-peak periods.

Despite a shift towards greener energy resources, natural gas still holds a significant market share as an energy source. As a result, manufacturers are continually developing new technologies that improve the efficiency of gas turbines. In this article, we explore the concept of efficiency of gas turbines, how to calculate it, and ways to improve turbine efficiency.