A load share controller plays a pivotal role in improving efficiency of multi-compressor systems. In this article, we explore how a load share controller works, benefits of using them, types, and considerations for selection.

What is a Load Share Controller?

A load share controller (LSC) is a sophisticated control system that coordinates multiple compressors operating in parallel. Working alongside capacity controllers, it ensures each compressor contributes optimally to the overall system demand. The controller receives capacity demand signals and intelligently distributes the load among operational compressors. By monitoring crucial parameters like surge margins and operating conditions, it maintains system stability and efficiency. Moreover, it prevents stronger compressors from overwhelming weaker ones, which could lead to inefficient operation.

Core Components

The load share control system consists of several key elements working in harmony:

- Primary capacity controllers that determine overall system demand.

- Individual load share controllers for each compressor.

- Power override controllers for electric motor-driven systems.

- Feedback selection mechanisms for system optimization.

- Capacity control interlocks for safety and stability.

How Load Share Controllers Work

Capacity controllers form the backbone of load-sharing systems. They actively monitor essential parameters such as pressure and flow to assess the total demand on the system. Once they gather this demand signal, they efficiently distribute it to individual load share controllers. These controllers then make continuous adjustments to speed or guide vanes to ensure that surge margins remain equal across the system. This coordinated method not only prevents unnecessary recycling but also optimizes energy consumption. Additionally, the load share control system includes protective features like power override controllers. Feedback signals from each compressor’s surge margin are sent back to the capacity controllers, allowing for real-time optimization. This seamless communication ensures that the entire system operates efficiently and safely at all times.

Types of Load Share Controllers

Modern load share controllers come in various configurations to meet different operational needs.

Capacity-based Load Share Controllers

Capacity-based load share controllers focus on the operational capacity of each compressor within the system. Moreover, these controllers utilize data related to the capacity utilization of the compressors to allocate load efficiently.

Functionality:

- Monitor the capacity output of each compressor in real time.

- Distribute the load among compressors to ensure that no single unit is overworked while others remain underutilized.

- Maintain a balanced system that can adapt to variations in demand by adjusting the operational capacity of each unit.

Applications:

Ideal for environments where compressor loads fluctuate frequently, such as manufacturing facilities and HVAC systems.

Surge Margin Load Share Controllers

Surge margin load share controllers focus on maintaining the operational stability of compressors by ensuring that they operate within safe surge margins. When the compressor flow rate drops below a certain threshold, surge occurs, leading to severe operational issues.

Functionality:

- Continuously monitor the surge margins of each compressor.

- Adjust load distribution to maintain adequate distance from surge limits across the compressor network.

- Prioritize the operation of compressors that are furthest from their surge points to optimize system reliability and efficiency.

Applications:

Particularly useful in systems where compressor operating conditions can cause surge, such as in the oil and gas industry or refrigeration applications.

Power-based Load Share Controllers

Power-based load share controllers operate based on the electrical power consumption of each compressor. These controllers manage compressors to optimize energy efficiency and reduce operational costs.

Functionality:

- Measure the power draw of each compressor and use this data to balance the load distribution.

- Ensure that the combined power usage of the compressors aligns with the overall demand, minimizing energy waste.

- Facilitate smoother transitions between compressors, especially during load changes, which can prevent spikes in energy usage.

Applications:

Common in industrial settings where energy costs are a significant concern. For example, in large manufacturing plants where multiple compressors operate simultaneously.

Benefits of Load Share Controllers

Utilizing load sharing systems comes along with several benefits as the following sections highlight.

Equal Throughput Flow

Load share controllers maintain an equal throughput flow (or capacity) across multiple compressor units connected to common suction and discharge lines, which helps to balance the load and optimize performance.

Higher Efficiency

By distributing the overall load between compressors, these controllers improve the efficiency of the entire system. This optimized load sharing reduces energy consumption and operational costs

Greater Reliability

Load sharing minimizes the risk of individual compressor overload, thus preventing premature wear and tear. This reliability extends the lifespan of the equipment and reduces maintenance needs

Surge Protection

These controllers help manage surge conditions by ensuring that compressors operate equidistant from their surge control lines, thus maximizing process efficiency

Improved Control and Monitoring

Load share controllers often incorporate advanced monitoring capabilities, allowing for real-time adjustments and better control over compressor operations. This leads to timely interventions if performance deviates from the desired parameters

Operational Flexibility

In environments with varying demand, load share controllers can dynamically adjust the operation of each compressor based on real-time conditions. Thus, providing flexibility and responsiveness.

Considerations for Load share Controller Selection

- Type of Compressors and Performance Characteristics: Understand the specific types of compressors in your facility (e.g., centrifugal, rotary screw) and their operational characteristics, as different compressors may require different control strategies.

- System Configuration: Evaluate the layout and configuration of the compressor system. Key details include piping and header sizes, because these factors influence the performance of load share controller.

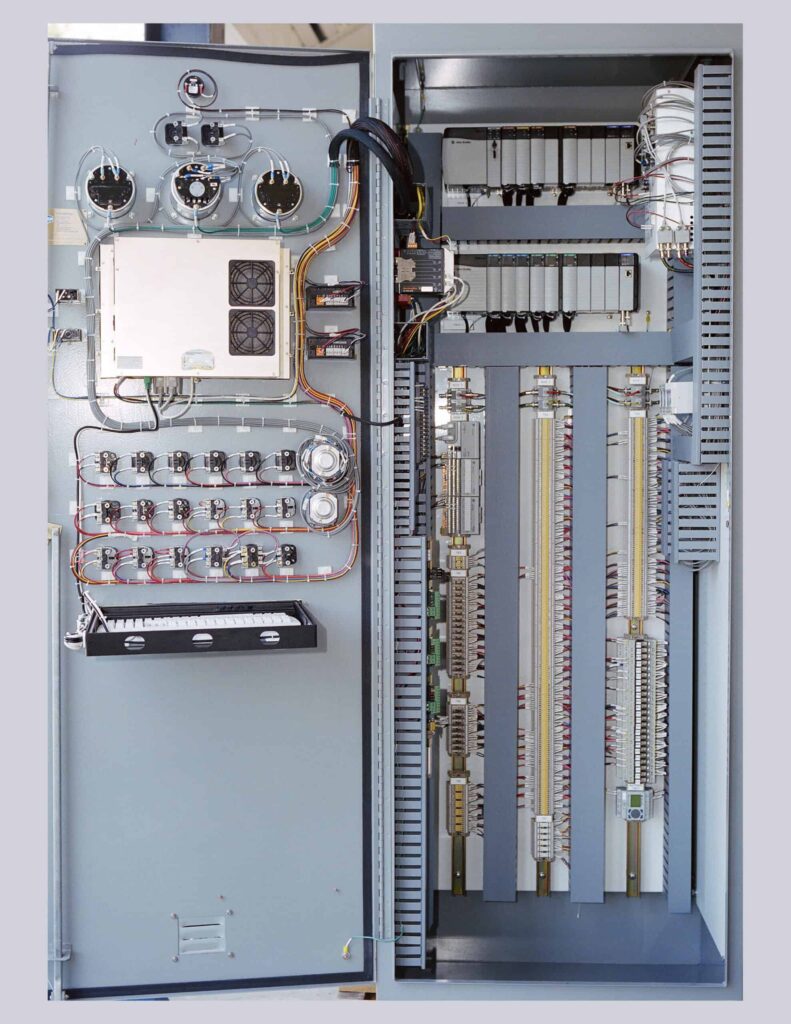

- Communication and Interfacing: Ensure that the load share controller can integrate with existing control systems, such as PLCs or DCS, to facilitate seamless communication and control.

- Cost Considerations: Evaluate the initial purchase price versus the expected return on investment (ROI). Consider both the long-term savings from optimized operations and maintenance costs when determining value.

- Support and Maintenance: Assess the level of technical support and maintenance services offered by the manufacturer or supplier. Adequate support can be crucial for maximizing the controller’s effectiveness over time.

Load Sharing vs Load Distributing

In compressor control, load sharing and load distribution are important concepts, which are often misconstrued. The following table highlights their differences.

| Feature | Load Sharing | Load Distributing |

| Focus | Maintaining equal surge margins across compressors. | Dividing the total load between compressors. |

| Approach | Adjusts individual compressor outputs to equalize surge margins. | Simply splits the total load on the basis of compressor capacities. |

| Considerations | Accounts for differences in compressor characteristics (head, capacity, as well as efficiency). | Does not actively manage individual compressor limitations. |

| Outcome | Prevents stronger compressors from overwhelming weaker ones. | May lead to some compressors operating inefficiently near surge. |

| Energy Efficiency | Optimizes energy consumption by minimizing recycling. | Can result in increased recycling, therefore leading to higher energy costs. |

| Operational Stability | Ensures stable operation by avoiding compressor surge. | May experience more instability and also compressor surge events. |

| System Coordination | Tightly integrates capacity and individual compressor control. | Operates compressors more independently without coordination. |

| Flexibility | Can adapt to changes in process conditions, as well as compressor degradation. | Less responsive to varying operating environments. |

Petrotech’s Approach to Load Share Controllers

At Petrotech, load share controllers (LSCs) are an integral part of our flexible and economical compressor control offerings. As a leader in compressor control solutions, we develop comprehensive LSCs that addresses common challenges in the use of multi-compressor systems. Our approach combines capacity-based and power-based control strategies, ensuring optimal efficiency and safe operation. Our LSCs continuously monitor the surge margins of the parallel compressors and adjusts their individual loads to maintain equal surge protection. In addition, our solutions are highly configurable, allowing for seamless integration with the overall control system. Its modular architecture enables easy deployment across various control platforms, thus, ensuring compatibility with your existing infrastructure. Contact us today for more details.