Recycle valves are crucial components in many industrial processes. Moreover, they help maintain the stability of pumps and compressors, preventing equipment damage and ensuring efficient operation. In this article, we explore what a recycle valve is, how it functions, as well as best practices for the right sizing.

What is a Recycle Valve?

A recycle valve, also known as an anti-surge control valve, is a specialized control valve. Its main function is to prevent damage to equipment such as pumps and compressors from low flow or high pressure. So, a recycle valve is typically dormant, but springs into action when these displacement equipment hit their minimum flow or pressure limit.

How Does a Recycle Valve Work?

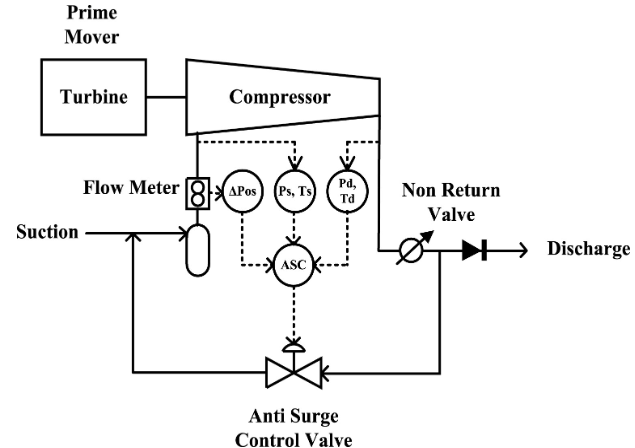

A recycle valve typically connects the outlet and inlet of displacement equipment, such as pumps and compressors, through a bypass line. When the flow drops to an unstable level, the valve automatically opens, rerouting fluid or gas back through the bypass to the system’s start. This action maintains minimum flow or pressure, ensuring the equipment’s safety.

The valve’s operation is usually automated, responding to signals from flow meters, pressure sensors, or other monitoring devices. These sensors continuously measure process conditions and, when approaching unsafe limits, prompt the valve to adjust accordingly. It opens or closes as needed to maintain stability.

Modern recycle valves often incorporate smart positioners, allowing for precise control and real-time monitoring of valve position. Additionally, they provide diagnostic information, which enhances overall system reliability.

Functions of a Recycle Valve

Recycle valves serve several critical functions in industrial processes, as the following sections highlight.

Recycle Valve in Surge Prevention

The primary function of a recycle valve is to prevent surge conditions. In compressors, sudden pressure changes can lead to a surge, which may damage the machine. A recycle valve manages pressure fluctuations by rerouting excess flow, effectively preventing surges.

Avoiding Cavitation in Pumps

Cavitation occurs when vapor bubbles form in a pump due to low pressure, potentially damaging the pump impellers and other components. The recycle valve maintains the flow rate at a level that reduces the likelihood of cavitation, thus protecting the pump from wear and tear.

Process Stability

Recycle valves ensure system stability in compressors and pumps, even under varying load conditions. They provide a fail-safe mechanism to keep equipment within operating parameters, especially during start-up and shutdown phases.

Energy Efficiency

Starting and stopping large pumps or compressors is energy-intensive and can accelerate equipment wear and tear. Recycle valves minimize these frequent stop-start cycles, contributing to overall energy efficiency and reducing maintenance costs.

Operational Flexibility

Recycle valves allow pumps and compressors to operate across a broader range of conditions. This flexibility is valuable in processes with varying demand, as well as during plant startup or shutdown. The ability to adjust system operation ensures smoother transitions and reliable performance under diverse scenarios.

Recycle Valve in Pressure Control

In certain applications, recycle valves help maintain specific pressure levels within the system. By opening or closing as needed, they adjust the backpressure on the pump or compressor, thus, ensuring the system stays within safe pressure limits and operates efficiently.

Recycle Valve in Temperature Management

For compressors handling gasses, recycle valves also manage discharge temperatures. By maintaining a minimum flow, they prevent excessive heating of the gas, which could otherwise lead to overheating and system damage. This temperature management is crucial for maintaining safe and efficient operation in gas compression processes.

How to Size a Recycle Valve

Sizing a recycle valve correctly is crucial for its proper function. An undersized valve cannot handle flow requirements, risking equipment damage. On the other hand, using an oversized valve may cause inefficiencies or pressure control issues. Here are best practices for sizing recycle valves for pumps and compressors.

Understand Operating Conditions

Begin by identifying the system’s minimum flow requirements. For pumps, manufacturers specify a minimum flow to prevent issues like overheating and cavitation. While for compressors, the surge curve is crucial as it defines the safe operating range, indicating where the compressor might experience surges. Understanding these operating conditions is essential to ensure the equipment operates safely and efficiently.

Calculate Flow Rate

The recycle valve must handle sufficient flow to keep the equipment within its safe operational range. To determine the recycling needs, use the system specifications, which include flow rate, pressure, and temperature. Calculate the amount of fluid or gas to recycle during low-load conditions to maintain stability and avoid operational issues.

Consider Valve Flow Coefficient

The flow coefficient, Cv, is a critical parameter in valve sizing. It defines the flow through the valve at a given pressure drop. Matching the valve’s Cv to the system’s flow requirements is essential. A low Cv restricts flow, potentially causing operational issues, while a high Cv can lead to instability and inefficient operation. Ensuring the correct Cv helps maintain optimal performance.

Factor in System Dynamics

Recycle valves often need to adjust flow quickly to respond to rapid system changes. Selecting a valve that can react swiftly is especially important in surge-prone systems or where rapid load shifts occur. The ability to respond quickly ensures the system remains stable and prevents damage to the equipment.

Account for Wear and Tear

Industrial valves face significant wear and tear over time. Therefore, selecting a valve designed for long-term durability is crucial. The valve should be capable of handling continuous operation demands. Consider using materials that are resistant to corrosion and cavitation, particularly in harsh environments. This will enhance the valve’s longevity and reliability.

Work with Experts

Collaborate with control system experts such as Petrotech to verify specifications and ensure optimal performance. At Petrotech, recycle valves are a crucial part of our Anti-Surge Control solution, which have been deployed for a wide variety of applications and configurations. Our engineering team will provide valuable insights into potential operational challenges and help you choose the correct valve size. Their experience and knowledge ensure that the selected valve will meet the system’s requirements and operate efficiently under various conditions. Contact us today for more information.