Gas turbine water injection is a critical technique for improving the efficiency and reducing emissions in gas turbines. This article reviews the benefits of gas turbine water injection including higher power output, lower NOx emissions, and better operational flexibility. We will also focus on how water injection helps meet emissions requirements for aging diffusion flame gas turbines.

Water Injection System

Water injection in gas turbines is a technique that serves to lower peak combustion temperatures for a given power output. Moreover, this method can be employed for two primary purposes:

- To reduce NOx emissions at a given power output

- To increase peak power while maintaining the same peak combustion temperature

It is also possible to achieve a combination of both effects, though to a lesser extent for each.

How Water Injection Works

Water is injected directly into the combustor of a heavy-duty gas turbine. Then, the water evaporates as it absorbs heat from the combustion process, effectively lowering the peak combustion temperature. This temperature reduction leads to decreased NOx formation and/or allows for increased fuel input without exceeding temperature limits. Thus, resulting in higher power output.

Components of a Typical Gas Turbine Water Injection System

A typical water injection setup includes the following components.

Water Source and Treatment

The water source could be a dedicated supply or existing treated water from a steam power plant. As for the water treatment requirements, it will depend on the water quality from the source. Common methods include reverse osmosis, deionization, and simple filtration.

Fuel Flow Measurement

- Gas Fuel Flow Measurement Assembly: Includes flow transmitter, pressure transmitter, temperature transmitter, as well as flow orifice flange union set.

- Liquid Fuel Flow Measurement Assembly: Typically a turbine-type liquid flow meter.

Water Injection Nozzles

Generally, there are two types available, which are:

- Water/Fuel Mixing Nozzles: Water and fuel mix upstream of the common nozzle tip.

- Separate Water and Fuel Nozzles: Water and fuel injection occurs separately.

Water Injection Pump and Flow Control Unit

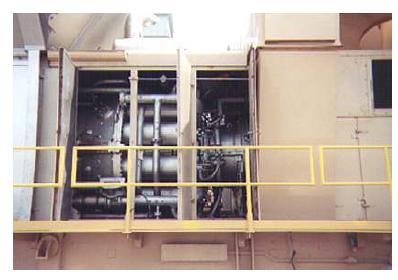

A skid-mounted assembly including:

- Filter/strainer

- Pressure and also temperature indicators

- Pressure safety switch

- Electric motor-driven centrifugal water pump

- 3-way stop valve

- Liquid flowmeter

- Skid base and support structure

Control and Monitoring Systems

- Water Injection Controller: Either a complete hardware and software control panel or an application software package.

- Integration with existing gas turbine control systems.

Additional Components

- Installation piping and wiring

- Motor controller and protection devices

- Commissioning equipment

- Training materials and support

This comprehensive system allows for precise control of water injection rates, ensuring optimal performance in terms of emissions reduction and/or power augmentation while maintaining safe and efficient turbine operation.

Benefits of Water Injection in Gas Turbine

Water injection in gas turbines offers several significant advantages that make it an attractive technology for power generation and industrial applications. The following sections highlight some of these benefits.

Higher Power Output

Water injection enhances engine power output by increasing mass flow rate and improving cooling capacity. The injected water adds mass to the intake air, allowing more fuel to be burned, while its evaporation cools the intake charge and combustion chamber. Moreover, this cooling effect increases charge density, reduces knock tendency, and allows for more aggressive ignition timing and higher compression ratios. The combination of higher mass flow, better cooling, as well as the expansion of steam during combustion all contribute to higher power output.

Lower NOx Emissions

One of the primary advantages of water injection in a gas turbine is its ability to reduce nitrogen oxide (NOx) emissions.

- Water vapor absorbs heat, hence lowering peak combustion temperatures.

- Reduction in temperatures inhibits NOx formation.

- Also, it is common to achieve NOx reductions of 60-80%.

Improved Operational Flexibility

Water injection enhances the operational flexibility of gas turbines by:

- Allowing for better performance across varying loads.

- Enabling faster response to changing demand.

- It also extends the operating range of the turbine.

Case Study: Water Injection for NOx Reduction to Dual Fuel GE Frame 5 Gas Turbine

Recently, Petrotech provided a Water Injection Skid used for NOX reduction on a dual fuel GE Frame 5 to one of the New York States Power utility providers. This Power utility provider contacted Petrotech after New York passed a law that by May 1, 2025, the limit is 25 ppm of NOx for gaseous fuels and 42 ppm of NOx for distillate oil or other liquid fuel. Thus, Petrotech developed simulation software to show this Power provider the level that we can get to with our control system/ Skid package. Petrotech then designed, built, delivered, and installed a test Skid for the GE Frame 5 and GE Frame 7 units. To assess the efficacy of this installation, there was testing on the GE Frame 5 first with the following results:

- A reduction in the original NOx emissions from 64.5 to 20.3 ppm on Gas.

- Also, there was a reduction from 105.5 to 35 ppm of NOx on Liquid.

- In addition, the client was able to get more power (MW).

Because the test results on the Frame 5 matched those from the simulation, the customer decided to permanently install the skid on GE Frame 5 and not test the GE Frame 7. For more on this case study, please visit the Water Injection Skid for NOx Reduction white paper.

Meeting Emissions Requirements on Aging Diffusion Flame Gas Turbine Using Water Injection

A critical application of water injection technology is in addressing emissions challenges faced by aging diffusion flame gas turbines. As environmental regulations become increasingly stringent, operators of older turbines are under pressure to reduce emissions, particularly NOx, without undertaking costly replacements or major retrofits.

Challenges of Aging Diffusion Flame Turbines

Common features of diffusion flame combustors in older gas turbine designs include:

- Higher NOx emissions in comparison to modern dry low NOx (DLN) combustors.

- Also, limited options for emissions control without significant modifications.

- Potential for efficiency reduction, as well as higher maintenance needs as they age.

Water Injection as a Solution

Water injection offers a cost-effective and efficient solution for bringing these aging turbines into compliance with modern emissions standards:

- Retrofit Simplicity: Retrofitting water injection systems to existing turbines is possible with minimal modifications to the core engine design.

- Significant NOx Reduction: By lowering combustion temperatures, water injection can reduce NOx emissions by up to 80% in some cases. Therefore, bringing older turbines in line with current regulations.

- Maintained Performance: Unlike some emissions control methods that can reduce turbine efficiency, water injection often maintains or even improves power output and heat rate.

- Extended Service Life: By reducing thermal stress on turbine components, there is potential for longer operational life of aging equipment.

- Flexibility: It is possible to adjust water injection systems to optimize the balance between emissions reduction and performance. Therefore, allowing operators to meet varying regulatory requirements and operational needs.

Gas Turbine Water Injection with Petrotech

Petrotech specializes in customizing water injection solutions for aging diffusion flame gas turbines in the following ways:

- Tailored Design: Each system is engineered to match the specific characteristics of the turbine and the emissions targets.

- Advanced Controls: Our control systems ensure precise water injection rates across all operating conditions, maximizing emissions reduction while minimizing impact on turbine life and performance.

- Integration Expertise: With experience across various turbine models, Petrotech ensures seamless integration of water injection systems with existing turbine controls and infrastructure.

- Compliance Assurance: Petrotech works closely with operators to ensure their water injection systems meet and maintain compliance with local and national emissions regulations.

For more detailed information, you can explore our website and whitepapers.